Bengaluru | Industry & Manufacturing

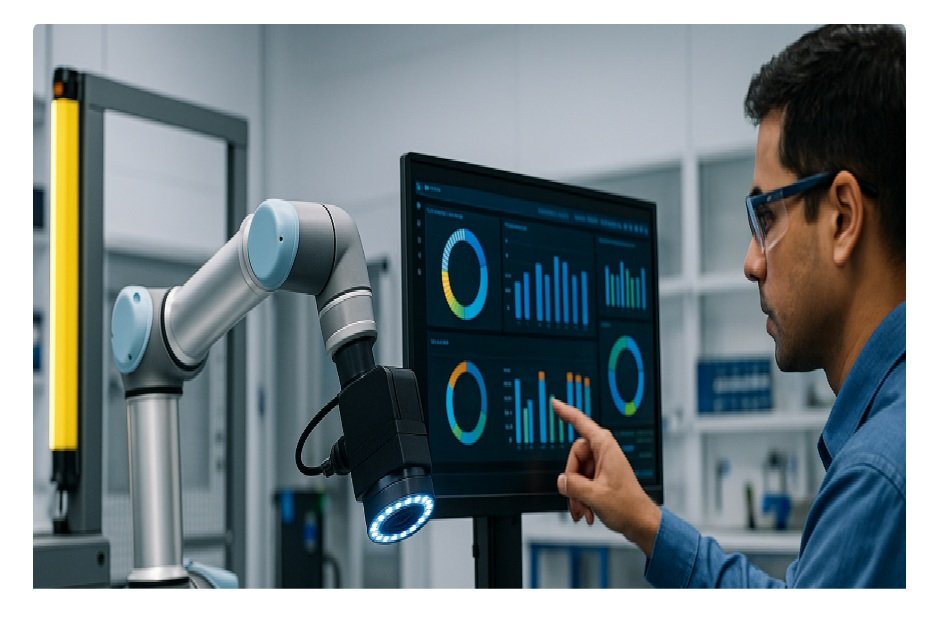

OMRON has opened a new Automation Center in Bengaluru, expanding its hands-on network of labs where manufacturers can design, test, and de-risk factory automation before committing capex. The facility brings sensors, safety, motion, machine vision, robotics and IIoT under one roof so Indian plants can prototype real production cells—then port proven settings to their own lines.

What the center actually enables

- Application labs / PoC bays: Teams can walk in with parts, CAD and process data to build proof-of-concept cells for inspection, assembly, packaging and intralogistics. Cycle time, OEE and changeover data are captured in the lab so ROI is visible before purchase orders.

- Robotics zone: Live demos of collaborative robots (cobots), SCARA/articulated arms and autonomous mobile robots (AMRs) integrated with conveyors, grippers and safety curtains—useful for machine tending, pick-and-place, palletizing and line-side material flow.

- Vision & AI inspection: A range of lighting, lenses and smart cameras for surface-defect detection, OCR/OCV, presence/position checks, and traceability with 1D/2D codes or RFID. Recipes can be tuned on customer parts to reduce false rejects.

- Motion, control & safety: Controllers, drives and safety PLCs help tune acceleration profiles, eliminate bottlenecks and achieve compliance with modern safety standards.

- IIoT sandbox: Gateways and dashboards for condition monitoring, predictive maintenance and energy metering, with hooks for MES/ERP connectivity and remote support.

- Training classrooms: Structured courses for plant engineers, system integrators and students on programming, commissioning and maintenance—turning pilots into sustainable operations.

Why Bengaluru, why now

Bengaluru anchors an automation triangle with electronics, EV/auto, aerospace and contract manufacturing nearby, plus a deep talent pool. Indian factories are under pressure to raise throughput, first-pass yield and energy efficiency while coping with SKU proliferation and skill shortages. A local center lowers adoption friction by offering:

- Faster design-to-deploy (settings proven in the lab can be cloned on site).

- Better business cases, using lab-measured takt and scrap data instead of assumptions.

- A partner hub for system integrators and OEMs to co-create domain-specific solutions.

Use-cases the center is primed for

- Automotive & EV: Battery cell/pack inspection, gasket dispensing, torque/press monitoring, EoL testing, AMR-based line feeding.

- Electronics: SMT/post-reflow vision checks, connector alignment, precision PnP with SCARA/cobots.

- FMCG & Pharma: Serialization/aggregation, blister and label inspection, hygienic conveying, case packing.

- Food & Beverage: Primary/secondary packaging, date-code verification, utilities energy analytics.

- Metals & General Engineering: Machine tending, weld/geometry inspection, safety retrofits for legacy equipment.

What success will look like

- Pilot-to-plant conversions: A rising share of PoCs turning into full-scale deployments within 6–12 months.

- Partner ecosystem depth: More certified integrators and pre-engineered “solution packs” (e.g., EV battery inspection kits, pick-to-light + AMR intralogistics).

- Upskilling throughput: Hundreds of engineers trained annually, reducing commissioning and downtime at plants.

- Sustainability impact: Projects that quantify scrap reduction and energy savings, not just cycle-time gains.

The bigger picture

India’s transition from islands of automation to interoperable, data-driven lines is accelerating. By letting users test on real hardware, benchmark results and transfer validated recipes to the shop floor, OMRON’s Bengaluru center turns buzzwords like AI vision, cobots and IIoT into measurable outcomes—higher OEE, better quality, safer operations and faster changeovers. For manufacturers balancing growth with cost discipline, it’s a pragmatic way to modernize without guesswork.